Factory Audit is on-site checking for the factory against the standards and customers’ requirements to evaluate the conformity.

Factory Audit covers:

Quality and technical competence Audit

Through on-site checking and evaluation of the factory’s legality, production capacity and quality management system, GIS ensures the clients to sufficiently understand the factory before the cooperation is confirmed so that to lower the risk of purchase.

Our duties:

![]() Check Legality and basic information of the factory;

Check Legality and basic information of the factory;

![]() Evaluate the production capacity and equipments management ( including production equipments and inspection equipments);

Evaluate the production capacity and equipments management ( including production equipments and inspection equipments);

![]() Check and evaluate the process control and quality control;

Check and evaluate the process control and quality control;

![]() Check and evaluate nonconforming products control, statistical analysis and quality improvement;

Check and evaluate nonconforming products control, statistical analysis and quality improvement;

![]() Check and evaluate supplier management;

Check and evaluate supplier management;

![]() Check and evaluate warehousing management for raw materials, semi-finished products and finished products;

Check and evaluate warehousing management for raw materials, semi-finished products and finished products;

![]() Check and evaluate post delivery service.

Check and evaluate post delivery service.

Code of Conduct (COC) Assessment

Code of Conduct (COC) assessment is to evaluate implementation and performance of social accountability based on SA 8000. The aim is to ensure that your business partners abide by the social accountability and ethics standards and norms so that to maintain your company’s brand.

Main elements of a typical code of conduct:

![]() Child labor;

Child labor;

![]() Discrimination;

Discrimination;

![]() Health & Safety;

Health & Safety;

![]() Disciplinary practices;

Disciplinary practices;

![]() Working hours and working condition;

Working hours and working condition;

![]() Dormitory facility;

Dormitory facility;

![]() Social warfare, remuneration and minimum wage;

Social warfare, remuneration and minimum wage;

![]() Management ;

Management ;

![]() Environment protection.

Environment protection.

Factory information confirmation

Through factory information confirmation, GIS can help clients confirm the factory’s authenticity before signing the agreement. To make sure the factory’s information, we will check the factory’s legal qualification, organizational structure, human resource, main products, work place, etc. on site.

Our duties:

![]() Factory location and background check;

Factory location and background check;

![]() Legal qualification documents check;

Legal qualification documents check;

![]() Certification check ( system certification, product certification);

Certification check ( system certification, product certification);

![]() Factory organization and human resource check;

Factory organization and human resource check;

![]() Main products check;

Main products check;

![]() Workshop and production line arrangement check;

Workshop and production line arrangement check;

![]() Storage and warehouse condition check (if needed).

Storage and warehouse condition check (if needed).

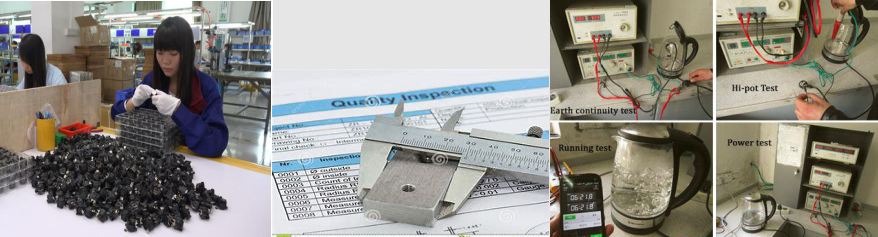

Inspection

Product inspection is divided into pre-production inspection, during production inspection and pre-shipment inspection.

Pre-Production Inspection

Pre-production inspection is to be conducted at the beginning of production or even before the start of manufacturing.

Our duties

![]() Check the raw materials and components used in production;

Check the raw materials and components used in production;

![]() Select samples of semi-finished products to detect potential defects;

Select samples of semi-finished products to detect potential defects;

![]() Evaluate the quality system of the production line;

Evaluate the quality system of the production line;

![]() Assess the management and ability of production equipments;

Assess the management and ability of production equipments;

![]() Assess the production capacity of the manufacturer;

Assess the production capacity of the manufacturer;

![]() Provide technical advice to the factory to improve product quality and minimize defects;

Provide technical advice to the factory to improve product quality and minimize defects;

![]() Assess production schedule.

Assess production schedule.

Your benefits

Find existent and potential problems before mass production to avoid unnecessary loss. Ensure consistence of product specification and production schedule

During Production Inspection

During-production inspection is to be conducted when 10%-15% of the production is completed.

Our duties

![]() Evaluate products for safety, performance, design, function and appearance;

Evaluate products for safety, performance, design, function and appearance;

![]() Check for any defects and deviation from clients’ specifications and/or given samples;

Check for any defects and deviation from clients’ specifications and/or given samples;

![]() Evaluate the packing methods and packing material;

Evaluate the packing methods and packing material;

![]() Check and evaluate the quality management of production line;

Check and evaluate the quality management of production line;

![]() Evaluate the production progress against the schedule and predict if the shipment is on schedule;

Evaluate the production progress against the schedule and predict if the shipment is on schedule;

![]() Give practical and effective advices to improve quality in accordance of the findings.

Give practical and effective advices to improve quality in accordance of the findings.

Your benefits

It is suitable for control of the production quality during the mass production. Ensure that the progress, production cycle and the quality meet clients’ requirements through as early as possible discovering and processing the quality problems.

Pre-Shipment Inspection

Pre-shipment inspection takes place when the merchandise is finished, packed and ready for shipment. Sampling is implemented in accordance with the internationally recognized acceptance sampling standards, e.g. ISO2859/ANSI/ASQCZ1.4 /BS6001/DIN40080/NFX06-022, etc.

Our duties

![]() Check quantity, accessories, assortment, labeling, shipping mark, etc. against the purchase order, given samples and technical documents;

Check quantity, accessories, assortment, labeling, shipping mark, etc. against the purchase order, given samples and technical documents;

![]() Evaluate product for safety, design, function, appearance, and performance;

Evaluate product for safety, design, function, appearance, and performance;

![]() Check for any defects and deviation against the technical standards or requirements;

Check for any defects and deviation against the technical standards or requirements;

![]() Assess packaging form.

Assess packaging form.

Your benefits

It is the final inspection with which you are be able to decide to accept the batch/lot of the merchandise or not.

Full inspection is 100% inspection for products, which is carried out before or after packing. Based on clients’ requirements, we will check product piece by piece on appearance, workmanship, function,safety and etc.

Our duties

![]() Appearance check;

Appearance check;

![]() Workmanship check;

Workmanship check;

![]() Function check;

Function check;

![]() Safety check;

Safety check;

![]() Other special checking points.

Other special checking points.

All defective products will be sorting out, qualified products which pass inspection will be packed (or re-packed)into carton and sealed with GIS label. It ensures that each product delivered meets our customer’s specified quality requirements.

Loading supervision

GTS suggests you use our Container Loading Supervision ( Container Loading Inspection, Container Loading Check, CLS) service. It happens in the manufacturer's warehouse or the forwarder's premises.

Not only the loading of the correct products and its quantity are supervised during the Container Loading Supervision ( Container Loading Inspection, Container Loading Check, CLS) but also the correct packaging and the quality of the goods are inspected. A report with full information and photos will be emailed to you within 24 hours. By that report, you will know the whole container loading process and your products inside the container

Below items checked when Container Loading Supervision / Inspection / Check:

![]() Record down the container loading conditions (weather, arrival time of containers, container number, truck number etc…)

Record down the container loading conditions (weather, arrival time of containers, container number, truck number etc…)

![]() Inspect the packing ways of your products including the shipping mark, carton dimension, gross weight etc.

Inspect the packing ways of your products including the shipping mark, carton dimension, gross weight etc.

![]() Verify the quantity of goods put into the container when performing the container loading supervision( Container Loading Inspection, Container Loading Check, CLS)

Verify the quantity of goods put into the container when performing the container loading supervision( Container Loading Inspection, Container Loading Check, CLS)

![]() Verify if the products are the ones you want. We will randomly draw some samples to check the general quality for you during the container loading supervision ( Container Loading Inspection, Container Loading Check, CLS)

Verify if the products are the ones you want. We will randomly draw some samples to check the general quality for you during the container loading supervision ( Container Loading Inspection, Container Loading Check, CLS)

![]() Record down the container loading process with photos

Record down the container loading process with photos

![]() Record down the seal number of container

Record down the seal number of container

Your benefits by using our Container Loading Supervision ( Container Loading Inspection, Container Loading Check, CLS) service:

![]() Reduce the risk of wrong quantity, wrong products, or damaged merchandise shipped

Reduce the risk of wrong quantity, wrong products, or damaged merchandise shipped

![]() Improve your sourcing efficiency

Improve your sourcing efficiency

![]() No need for you to be on-the-spot. Save your money, save your time!

No need for you to be on-the-spot. Save your money, save your time!